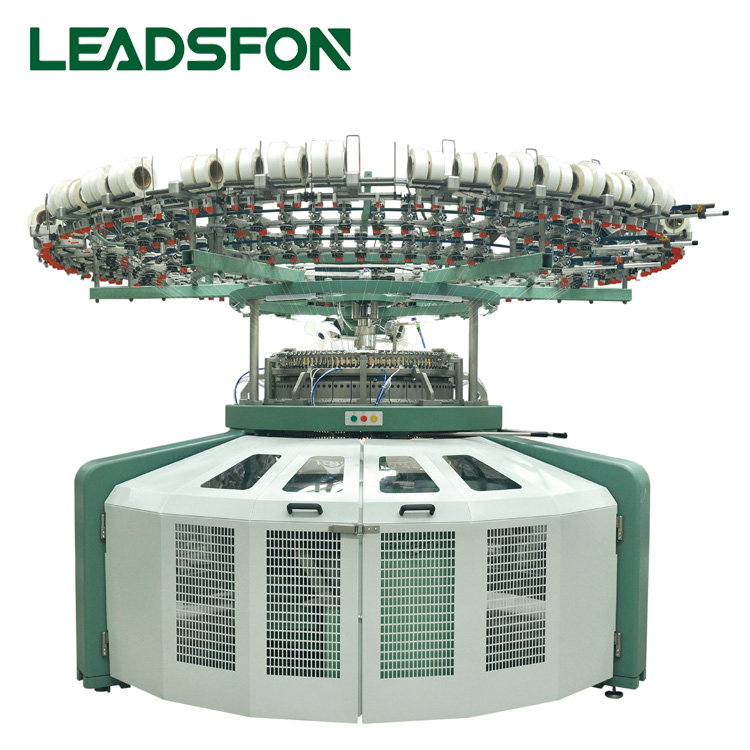

High Quality for Leadsfon Knitting Needle Machine - Lycra Feeder used for yarn storage feeder device for circular knitting machine – Leadsfon Detail:

Main features

1.The integrated wire feeding roller and all-metal shell can achieve high-precision yarn feeding, which can effectively improve the quality of the cloth surface.

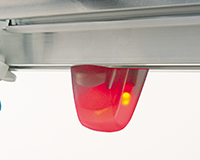

2.The integrated LED indicator light can facilitate the operator to quickly find the position of yarn breakage and improve work efficiency.

3.The yarn breaking automatic stop device adopts a mechanical lever structure, and the counterweight can be adjusted according to the tension of the spandex. After yarn breaking, the light path is blocked and the yarn breaking stop signal is triggered.

4.The use of optical technology can only analyze the condition of the yarn breakage automatic stop system, and issue a cleaning reminder in time through the yarn breakage.

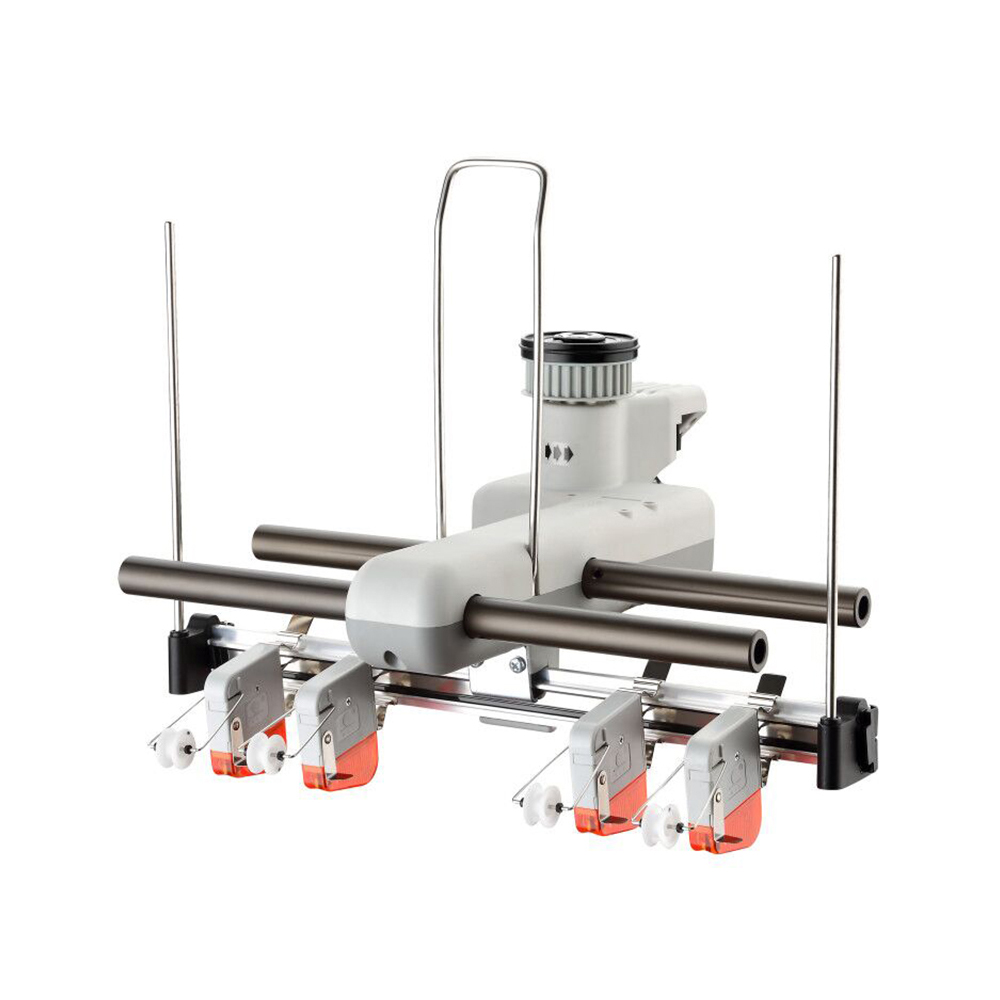

MER 4 Elastane roller

| Item NO. | Lycra Feeder |

| Product Origin | Jangsu, China |

| Lead Time | 3-7 working days |

| Warranty | 1 year |

| Rated voltage (machine stoppage) | 12/24 V AC/DC |

| Rated current | 25 mA |

| Yarn Tension | Min 0.8cN (centiNewton) |

Application

The MER 4 is a universal elastane roller designed for the positive feeding of plain elastane yarn to large-diameter circular knitting machines. This new version of the elastane roller has been developed to process plain elastane at even lower yarn tensions.

Main features

1.Available with sensor unit Standard (S), Roller (R) and Performance (P)

2.Completely newly developed sensor unit system Performance (P) which ensure working with lowest yarn tension also at highest machine speeds. This is characterised in particular by improved sliding and gliding properties of the yarn deflection bolt and the more compact design which is less susceptible to contamination.

3.Highly versatile. The unit has a single ratio only and is therefore suitable for all current machine types.

4.Compact dimensions, minimum space requirement.

5.High-visibility central warning light. The operator sees warnings sooner, this cuts yarn breakage downtime and increases knitting machine production rates.

1. Self-stop system

The self-stop system operates with gravity. When the yarn is broken, the non-contact magnetic force drives the automatic stop system.

2. Colored stop indicator

The warning light is centrally and highly identifiable below the yarn feeder. The casing discolors when the yarn breaks and stops.

3. Dust cover (optional)

The dust cover prevents wind wool from contaminating the elastic yarn, reducing loom downtime and fabric contamination. Thus increasing the loom capacity.

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for High Quality for Leadsfon Knitting Needle Machine - Lycra Feeder used for yarn storage feeder device for circular knitting machine – Leadsfon , The product will supply to all over the world, such as: Benin , French , Latvia , Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!